Exploring the Robotic Revolution of Actuators and CNC – The ancient civilizations that utilized windmills and water clocks are the ones that gave rise to automation, the technological marvel that has reshaped industries. The desire for efficiency spawned more complex machines over centuries, paving the way for the smart factories and robotics of today. Integral to this cutting-edge mechanization account are straight actuators — the overlooked yet truly great individuals guaranteeing exact movement.

So, what is a linear actuator exactly? A gadget moves in an orderly fashion, diverging from the roundabout movement of a regular engine. Despite the simplicity of the mechanisms, there is a world of diversity.

A variety of applications can be served by electric, hydraulic, pneumatic, and even piezoelectric actuators, each with its strengths. As we venture into the circle of robotization, perceiving the force of these accuracy-driven gadgets becomes vital.

The margin of error decreased as industries expanded. The Industrial Revolution’s mechanical looms evolved into computer-controlled assembly lines, a progression from simple, manual mechanisms to advanced automation at its zenith. Through everything, the quest for pinpoint exactness stayed steady.

Advancements in Linear Actuator Technology

As innovation advances, so does the artfulness of our instruments. Miniaturization is a significant development in linear actuator technology. Athletes are no longer bulky or obtrusive; the present plans are smaller, permitting them to settle into restricted spaces, making them well-suited for perplexing undertakings, from watchmaking to microelectronics gathering.

Combined with this size decrease is a stupendous jump in accuracy and effectiveness, guaranteeing undertakings are executed with the most extreme exactness, saving both time and assets. Moreover, present-day actuators gloat surprising sturdiness and life span, a demonstration of the better materials and designing practices utilized in their development.

Applications in Modern Automation

The sheer adaptability of direct actuators is apparent in their different applications:

- Medical: With actuator-powered robotic arms, surgeons can now carry out intricate procedures with unprecedented precision. In a similar vein, drug dispensing has evolved into an automated art form that guarantees precise dosages with minimal error.

- Industrial: The assembling scene has been changed via mechanized sequential construction systems and CNC machines, all of which depend on the accuracy of actuators to deliver reliable, excellent items.

- Aerospace: In the boundlessness of room, precision is foremost. Linear actuators are essential for maintaining aircraft’s intricate parts and making minute adjustments to satellites.

- Life Every Day: The comforts we frequently underestimate, from computerized blinds to assistive gadgets helping those with versatility challenges, owe their usefulness to the unobtrusive force of straight actuators. Their profound impact on our day-to-day lives is frequently obscured by their quiet operation.

Benefits of Enhanced Precision

As the hardware of our reality tweaks its accuracy, we receive plenty of rewards:

- Errors will be reduced: Defects in manufacturing become less common as precision increases. This guarantees high item quality as well as supports buyer trust and brand notoriety.

- Cost reduction: Accuracy likens to consistency, prompting a critical decrease in squander. By guaranteeing proficient utilization of assets, organizations can accomplish more noteworthy benefits and diminish their natural impression.

- Safety: Precision tools reduce the need for human intervention in high-risk locations, particularly those where human lives are at risk. Employees are protected from potential dangers and tasks are carried out with unwavering precision as a result of this.

The Role of Actuators in Robotics

In the domain of mechanical technology, actuators hold an essential job. They are the parts that, by converting energy into motion, give robots the ability to interact with their surroundings. Robots can carry out a wide range of simple to complex tasks thanks to this conversion process.

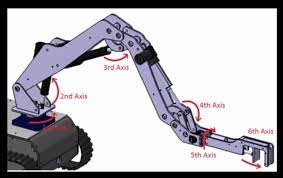

Actuators are the main impetus behind a robot’s capacity to move. They are the parts of the robot that respond to signals from the control system and move in the right direction. This could be as straightforward as turning a wheel or as difficult as coordinating the movements of a robotic arm with multiple joints.

The job of actuators reaches out past development. Additionally, they help the robot sense and respond to its surroundings. For example, in a mechanical arm utilized in an assembling plant, the actuators empower the arm to move, yet in addition give criticism to the control framework about the arm’s situation and development. This criticism, known as proprioceptive data, is vital for the robot to perform exact developments.

The robot’s performance and effectiveness can be significantly impacted by the actuator type used. For instance, electric actuators, which convert electrical energy into mechanical movement, are known for their high velocity and accuracy. They are often found in robots that need to move quickly and accurately, like those used in assembly lines or for surgeries.

Then again, water-driven actuators, which utilize compressed liquid to move, are known for their high power and power. They are often utilized in robots that need to perform rock-solid errands, like those utilized in development or modern robotization settings.

Pneumatic actuators, which utilize packed air to create movement, offer benefits concerning straightforwardness, lightweightness, and minimal expense. They are frequently available in robots that are simple, repetitive tasks like sorting or packaging.

Conclusion

As we look forward, the skyline is overflowing with potential outcomes:

- Incorporation of AI: The marriage of man-made brainpower and actuator innovation guarantees another variety of shrewd actuators. Not only will these devices carry out their tasks, but they will also continuously learn, modify, and improve their operations.

- Sustainable progress: As the world turns towards maintainability, energy-effective actuator plans are arising. These green developments lessen functional expenses as well as add to a better planet.

- Expected in strange domains: Linear actuators have yet to be fully utilized in their capabilities. These precise instruments will be at the forefront of our exploration of the vastness of space and the deep sea, assisting in the upkeep of space installations and deep-sea exploration.