With the latest printers now being released with built-in auto bed level sensors, it is now becoming a norm for printers to have the feature, whether it comes built-in or not. More and more auto bed level (ABL) sensors are now becoming available in the market, especially in online shops such as Lazada and Shopee. For those with printers without the ABL feature, what kind of ABL sensor should one get?

The three types of ABL sensors available in the market are Capacitive, Inductive, and Physical-Hall Effect. Each type of sensor provides different strengths, and choosing one over another depends on a person’s preference. Here, we’ll be providing the strengths of each sensor, as well as their pros and cons.

Why?

Although the auto bed leveling feature is not a must, it’s one of the best upgrades you can make to your 3D printer. It provides better performance and ease of use. However, some may argue that the ABL feature is not necessary since they have been printing long before the feature was even introduced in the market. Once again, this all depends on a person’s preference and ability to acquire one.

Keep in mind that the feature says “auto bed level,” but the process does not actually adjust the bed physically. This feature uses the ABL sensor to map the bed’s positioning to create a topological map for the nozzle to follow. Also, upgrading to a setup with an ABL feature calls for upgrading the printer into a solid mount bed, removing the bed springs.

Capacitive Sensor

As the name indicates, a capacitive sensor is a non-contact sensor that detects both metallic and non-metallic surfaces. The sensor can detect any build surface by comparing the dielectric constant of the surface with air. This type of sensor monitors the capacitance of its onboard capacitor, which changes in value depending on what kind of material is placed near its sensing face.

The downside of this sensor is that its ability to gauge the distance of the bed will depend on the surface type, the environment’s humidity, and the temperature. This is usually not a problem when the build plate remains constant and not changing between prints (switching between other materials such as glass, PEI, polypropylene, etc.).

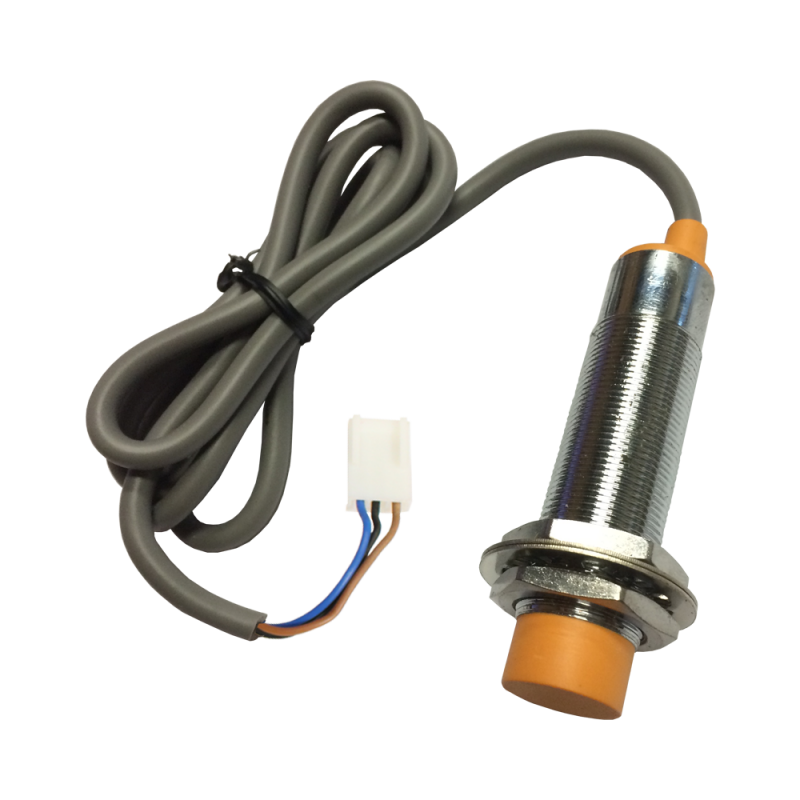

Inductive Sensor

Another non-contact sensor would be the inductive sensor. This sensor is accurate when detecting metallic surfaces. Both the inductive and capacitive sensors may look alike, but the principle they operate to detect surfaces is entirely different. Inductive sensors use inductance, an electrical principle wherein an inductor coil creates a magnetic field that fluctuates when a metallic object is brought within its sensing distance. Non-metallic objects have no effect.

In the case of a PEI print bed setup, the sensor detects the spring sheet that the PEI material is adhered to and not the actual PEI surface that the filament is printed on.

The downside of this sensor is similar to that of the capacitive sensor; temperature and humidity can easily affect the sensor’s readings. The drastic temperature change can significantly affect the sensor.

Physical-Hall Effect

The physical-hall effect sensor is the only sensor that makes contact with the print bed in order to map the bed. Due to this, the physical-hall effect sensor isn’t affected by temperature, humidity, or airflow. This sensor operates by using a plastic pin and a hall effect sensor. When the sensor approaches the print bed, the plastic pin will retract as soon as it touches the bed; this will get registered by the hall effect sensor. The plastic pin has a magnet embedded at the top, which is what the hall effect sensor detects.

The main downside of this type of sensor is the time it takes for it to map the bed. Compared to the capacitive and inductive sensor, the physical-hall effect must touch the print bed and then reset the pin to prepare for the next point to map. Another issue is the presence of moving parts. In concept, more parts equal more possible causes of breaking or wear-and-tear. The upside is that there are few parts, making it easy to replace. The pin is made of plastic so that it can be flexible and not prone to breakage.

Comparison

The results for the comparisons are based on an experiment conducted by 3D Maker Engineering.

Accuracy

When it comes to accuracy, all three sensors live up to their roles as bed level sensors. This was tested in an environment wherein temperature and build surfaces were constant throughout the test. The result is a tie among the three.

Versatility

The test for versatility was done by varying the print surface as well as slightly varying the ambient temperature. In theory, the two non-contact sensors should come out the winners. However, after the experiment, the physical Hall-Effect sensor came out on top.

With the temperature set to 35°C, the conductive and capacitive sensors could not successfully print their first layers. Since the physical Hall-Effect sensor is not affected by print surface or temperature, it could map the build surface better.

Probing Speed

With the inductive and capacitive sensors requiring not requiring contact with the bed and the absence of moving parts, the two sensors are faster than the physical Hall-Effect sensor. With the newer firmware, Marlin 2.0, the probing speed of the physical Hall-Effect sensor is faster through the HSMode feature. However, the physical Hall-Effect sensor is still 10% slower than the others. Therefore, it is a tie between the inductive and capacitive sensors.

Durability

As far as durability goes, the three sensors are a tie. In theory, however, the physical Hall-Effect sensor is more prone to wear and tear due to the presence of moving parts, but all three sensors should last a long time.

Cost

When it comes to cost, bias tends to influence the decision. In the spirit of neutrality, it’s best to say that each sensor would vary in prices depending on the brand, build quality, and seller.

Conclusion

All three types of sensors can do the job that they were made for. It is simply about keeping in mind that it’s best to have a controlled environment: no drastic changes in ambient temperature and maintaining one kind of build surface.

With printing environments that are constantly changing or not controlled, it’s best to go with the physical Hall-Effect sensor since it is insusceptible to temperature and the type of build surface is not limited.

Reference

3D Maker Engineering. (n.d.). Auto bed levelling (ABL) sensor comparison. Retrieved from: https://www.3dmakerengineering.com/blogs/3d-printing/auto-bed-leveling-sensor-comparison