With more and more types of filaments becoming available in the market, it’s important to keep in mind the effects of filaments on your printer and person. A goal in 3D Printing is to keep printing as efficiently and continuously as possible. In order to do that, wear and tear of components need to be included in the thought process.

What is Abrasive Filament?

With more and more innovative 3D models and filaments to print models in new textures and color, the means to print them needs to keep up in terms of quality and durability. As the name implies, abrasive filament causes friction, grinding, and rubbing that wears out the components and equipment that it comes in contact with. These kinds of filaments usually combines two materials in order to strengthen and or create an exotic kind of filament. An example would be the wood filament, where PLA is combined with wood dust and other wood derivatives. Some commonly used abrasive filaments can be seen below.

Wood Filament

Wood filament produces models with a wooden texture and color. The model produced is relatively lighter than PLA and more delicate. Usual mixture is 70% PLA and 30% wood.

SteelFill

SteelFill is part PLA and part fine steel powder. Although this filament emphasizes on the color and texture of metal, it is still mostly PLA and will warp when exposed to direct sunlight.

Carbon Fiber

Infused with carbon fiber fragments, this filament excels in durability and strength. Carbon fiber filament produces lightweight and strong models, useful with models with mechanical uses.

What is affected?

The parts that are affected by abrasive filaments are those that come in direct contact with the filament, namely the nozzle and the Bowden tube (for Bowden Tube setups).

As the abrasive filament passes through the Bowden tube, it cuts and grinds on the inner lining of the tube. At first, this wouldn’t show any problems and would print normally. However, in the medium to long run, the wear and tear would cause friction inside the tube to increase, making it hard for filament to pass through. This results in the extruder’s stepper motor having to use more force and could possibly lead to under extrusion. With the Direct Drive setup, this issue is resolved due to the absence of a Bowden tube.

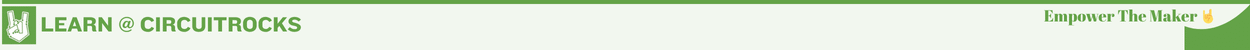

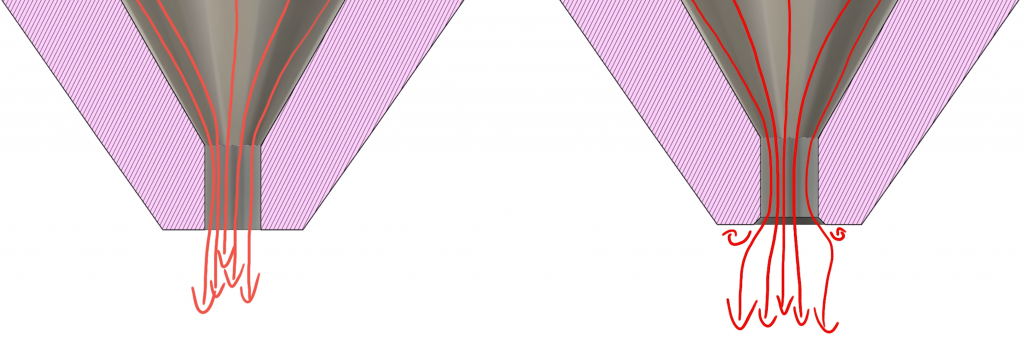

A more pressing issue would be the affect on the nozzle. Abrasive filaments can easily wear out brass nozzles. Based on an experiment by CNC Kitchen, how abrasive filament wears a nozzle out is observed. As shown in the image above, the nozzle tip is designed with a sharp angled opening. After 360 grams of abrasive filament, the tip appeared to be chamfered. This affects the flow of filament.

References

- N.a. (n.d.). Abrasive filaments. Retrieved from: https://learn.colorfabb.com/abrasive-filaments/

- Stevensons, K. (2019 October 26). Really, how bad are abrasive filaments for your 3d printer nozzle? Retrieved from: https://www.fabbaloo.com/blog/2019/10/26/really-how-bad-are-abrasive-filaments-for-your-3d-printer-nozzle

- CNCKitchen. (2019 September 28). How much abrasive filaments damage your nozzle! Retrieved from: https://www.cnckitchen.com/blog/how-much-abrasive-filaments-damage-your-nozzle